|

|

|

|

Fingerless type Single Facer Corrugator, Fingerless Vacuum Suction type, Steam Heating

Product Details:

Payment & Shipping Terms:

|

| Automatic Grade: | Automatic | Voltage: | 220v/380v/440v |

|---|---|---|---|

| Condition: | New | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Driven Type: | Electric | Certification: | CE |

| Warranty: | One Year | Name: | Corrugated Cardboard Single Facer Line |

| Color: | Customized Color | Machine Type: | Corrugated Paperboard Making Machine |

| Usage: | Corrugated Making |

1) SF-S Fingerless type Single Facer Corrugated Machine drive reducer box with oil immersed type lubricating to reduce noise keep running stable. Adopt gimbals transmission. Separate power.

2) Corrugating roller, pressure roller and glue roller by pneumatic adjustment.

3) Paper transmit adopt vacuum suction method, with wind control system, to keep flute profiles stable of the lower-roller in the condition of running up.

4) Bearing of corrugated and pressure roller adopt high temperature lubricate grease. Glue parts auto supply glue circularly.

5) Upper-lower corrugating rollers are made of 48CrMo high quality alloy steel, after heat-treatment. The hardness HRC58°-60°, surface after grinded. Gluing roller surface are treated by special mesh snick and chrome-plated.

6) Motorized or manual glue width dividing to match the paper width.

|

Max Effective Width |

1100~2200mm |

|

Flute Type |

customer-made |

|

Corrugating Roller |

Φ280~380mm, 48CrMo alloy steel, hardness HRC58°-60° |

|

Design Speed |

80~200m/min |

|

Heating Method |

Steam Heating |

|

Economic Working Speed |

60~160m/min |

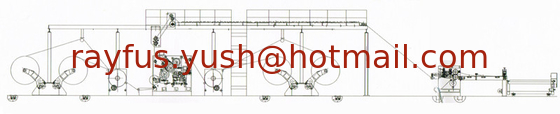

1) This product line consists of Hydraulic Shaftless Mill Roll Stand, Auto Splicer, Preheater, SF-320C Fingerless type Single Facer, NC Single Faced Slitter Cutter Stacker, Steam Boiler & Pipeline(customer-owned parts), etc.

2) Kraft Paper Reel to corrugate and glue by Corn Starch Gum, continuously produce and cut to Single Faced Corrugated Cardboard Sheet, and then through Flute Laminator Machine or Sheet Pasting Machine to laminate to 3/5-ply corrugated sheet, press and fix.

3) The production line has rational structure design, advanced producing flow, high efficiency, strong batch adjustability, easy operation, etc. Good work conditions.

4) It is the ideal and perfect equipment for small or medium carton factories.

| Max Effective Width | 1100~2200mm |

| Max Paper Roll Diameter | 1500mm |

| Max Paper Roll Weight | 3000kg |

| Corrugating Roller | Φ320mm, 48CrMo alloy steel, hardness HRC58°-60° |

| Cutting Length | 300~9999mm |

| Cutting Precision | ±1mm |

| Design Speed | 150m/min | |

| Heating Method | Steam Heating | |

| Economic Working Speed | 100~120m/min | |

![]()

![]()

![]()

![]()

Contact Person: Mr. Rayfus

Tel: +86-156-9019-6799

Fax: +86-318-573-6656

-

Single Facer Corrugation Line, Mill Roll Stand + Single Facer + Rotary Cutter

-

Electrical Shaftless Mill Roll Stand, Two Kraft Paper Reel, with Paper Car and Track Rail,

-

Single Facer Corruagtor Machine, Fingerless Vacuum Suction type, Steam Heating

-

NC Computer-control Rotary Slitter Cutter, Corrugated Cardboard Slitting + Cutting

-

High-Speed 2-Ply Corrugator Line, Single Faced Corrugated Cardboard Making Machine

-

Auto Splicer, with Hydraulic Shaftless Mill Roll Stand, for 2-ply Corrugated Cardboard Production Line