|

|

|

|

Automatic Flexo Printer Slotter Die-cutter Stacker Machine, Lead-edge Feeding, 1~5 color

Product Details:

Payment & Shipping Terms:

|

1) YKMD-Q Automatic Lead-edge Feeding Flexo Printing Slotting Die-cutting Stacking Machine can finish cardboard 1~5 color printing, slitting, scoring, slicing, slotting, die-cutting, creasing, stacking, etc. at one time.

2) Adopt vacuum adsorption lead-edge feeding cardboard, accurate and reliable.

3) Main motor adopts frequency conversion control and stays stable working.

4) PLC control, includes keeping records, speed, delivering paper in interval. Rubber roller moves up and down; malfunction alarm enunciator is controlled by electric motion automatically.

5) Each part is equipped with auto rise device.

6) Notch system adopts high-precision thread pole. with precise and reliable XKNC.

7) Each machinery group is shifted by electric motion and locked pneumatically.

8) Turning gear rubs precisely, equips with spraying and lubricating device which products less noise and can be used for a longer period.

9) Die cutter rubber roller strap revolving along the axis which helps to extend the using time of the rubber roller.

10) Electric control parts and main axletrees are implored so as to ensure their quality.

|

Max Sheet size |

900*1200mm~1600*3000mm |

|

Min Sheet Size |

300*400~500*600mm |

|

Max Printing Area |

900*1000mm~1600*2800mm |

|

Min Slotting Distance |

120*120*120*120mm |

|

Max Slot Depth |

225~400mm |

|

Max Die-cutting Size |

900*1000mm~1600*2800mm mm |

|

Max Stacking Height |

1500mm |

|

Design Speed |

120~180pcs/min |

Contact Person: Mr. Rayfus

Tel: +86-156-9019-6799

Fax: +86-318-573-6656

-

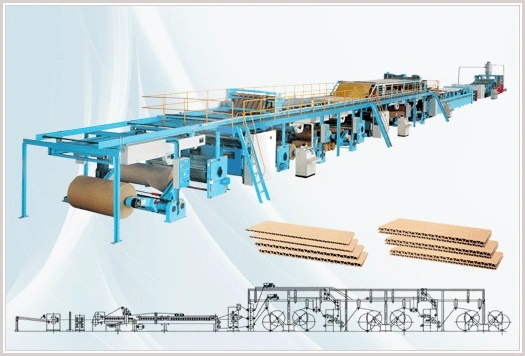

3/5/7-layer Corrugated Cardboard Production Line, Corrugated Cardboard Making Machine

-

Automatic Flexo Printer Slotter Die-cutter Folder Gluer Strapper Inline Machine, with PP or PE Strapping

-

Automatic Folder Gluer Stitcher Strapper All Inline One Machine, PP or PE strapping

-

Automatic Folder Gluer, Corrugated Carton Box Folding + Gluing, inline Strapping as option

-

Full Automatic Stitcher for Corrugated Carton Box, Gluing & Strapping as option

-

Automatic Flexo Printer Die-cutter Machine, Automatic Lead-edge Feeding, High-speed