|

|

|

|

Hydraulic Shaftless Mill Roll Stand + Auto Splicer, Two Kraft Paper Reel, with Paper Car and Track Rail

Product Details:

Payment & Shipping Terms:

|

1) ZJ-Y Hydraulic Shaftless Mill Roll Stand two sets of Paper Vehicle and Track Rail will be provided for each Mill Roll Stand, to transfer the Paper Mill Roll.

2) Adopt double symmetrical shafts with four arms; Support two paper mill rolls on both arms at the same time.

3) Hydraulic control for paper mill roll up-down, electrical clamp-open and centering.

4) Web tension is controlled by pneumatic brake or manual brake.

5) Automatic expansion springiness chucks to reduce paper waste.

|

Max Paper Roll Width |

1100~2200mm |

|

Max Paper Roll Diameter |

1500mm |

|

Max Paper Roll Weight |

3000kg |

1) Improving the efficiency of mill roll and mill roll can be fully used up

2) Zero tail splicing, the sticking area is quite small which can reduce the consumption

3) Non-stop slicing which can increase the working efficicency dramatically

4) Automatic tension control which indicates the advantages of easy operation and humanization

5) Simple and quick through structure which indicates the advantages of easy operation and humanization

6) Special design flatenning technology which can eliminate the wrinkle phenomenon dramatically

7) PLC control with high automation integrated level

| Effective Paper Width | 1100~2200mm |

| Paper Thickness | 50~350gsm |

| Design Speed | 150m/min |

![]()

![]()

![]()

![]()

Contact Person: Mr. Rayfus

Tel: +86-156-9019-6799

Fax: +86-318-573-6656

-

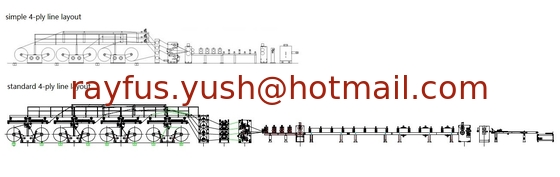

2/3/4/5-ply Industry Cardboard Production Line, Hard Grey Paperboard Manufacturing Plant

-

2/3/4-ply Hard Paperboard Production Line, Industry Grey Cardboard Manufacturing Plant

-

Preheater Machine, Preheating Roll, Duple, Triple, Quadruple Preheater

-

Paper Edge Aligning Machine, ultrasonic detecting + servo control, Duple, Triple, Quadruple

-

Gluing Machine, Single Gluer, Duple Gluer, Triple Gluer, for hard paperboard making

-

Pressing Section + Driving Unit + Heating Section + Cooling Section + Driving Unit